Introduction

Dip tube cutting is a critical but often underestimated step in the design of dispensing systems such as pumps, triggers and sprays. An incorrectly measured dip tube can lead to poor product evacuation, inconsistent dispensing or unnecessary waste, even when all other components are correctly specified.

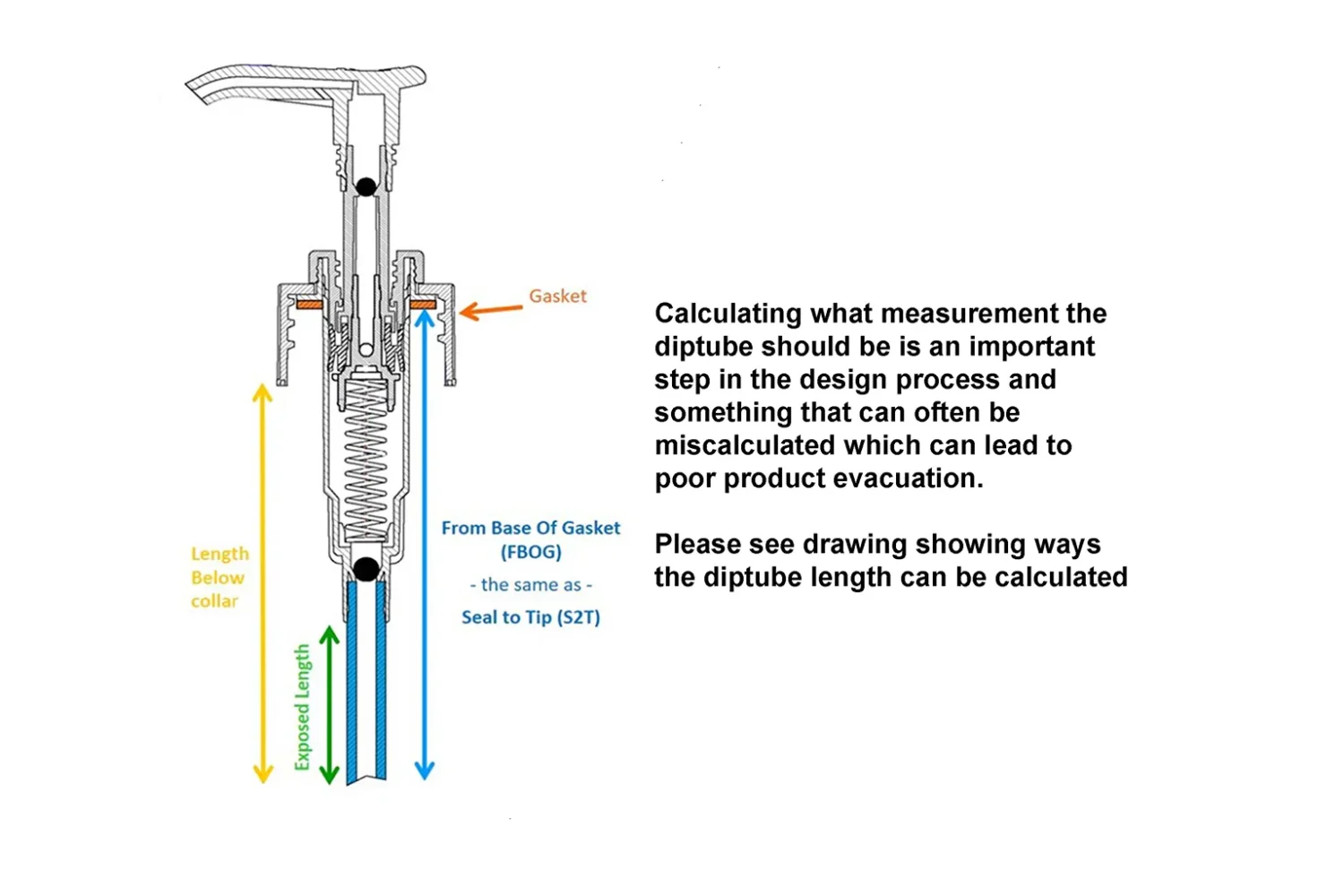

Understanding how dip tube length is calculated helps ensure that the dispensing system performs as intended across the full life of the product.

What is a dip tube?

A dip tube is the tube attached to the underside of a pump or closure that reaches into the container to draw up the product during dispensing. Its length determines how efficiently the product can be evacuated from the bottle.

Dip tubes are used across a wide range of dispensing formats, including lotion pumps, trigger sprayers, serum pumps and sprays, all of which follow the same basic measurement principles.

Why dip tube length matters

If a dip tube is too short, product may remain in the container and cannot be dispensed. If it is too long, the tube may bend, interfere with the base of the bottle or restrict product flow. Both scenarios can result in poor evacuation and inconsistent performance.

Accurate dip tube cutting supports:

- Consistent dispensing

- Improved product evacuation

- Reduced waste

- Better user experience

How dip tube length is measured

There are several reference points used when calculating dip tube length, and clarity at this stage is essential.

One common method is measuring from the base of the gasket (FBOG) to the tip of the dip tube. This measurement is often the same as seal to tip (S2T) and provides a reliable reference for most pump systems.

Other considerations include:

- Length below the collar

- Exposed length inside the container

- Bottle internal height and base shape

The diagram illustrates how these reference points relate to one another and why using the correct measurement method helps avoid miscalculation.

Common causes of miscalculation

Dip tube length is often miscalculated when assumptions are made based on nominal bottle sizes rather than actual internal dimensions. Variations in bottle base design, wall thickness and tolerances can all affect the final required length.

Without verification through sampling or testing, small inaccuracies can have a noticeable impact on performance.

Practical considerations across different dispensers

Although the diagram shows a lotion pump, the same dip tube cutting principles apply to triggers, serum pumps and sprays. Each format relies on correct tube length to ensure reliable product evacuation and consistent output.

Where performance is critical, sample testing is recommended to confirm that the selected dip tube length functions correctly with the chosen container and formulation.

Summary

Dip tube cutting is a small detail with a significant impact. Correct measurement helps avoid performance issues, supports efficient product use and contributes to a more reliable packaging solution overall.

Clear specifications and practical validation are key to ensuring dip tube length is calculated correctly from the start.